|

| |

| Softop Buckle |

|

| Under normal conditions,

with the rider's weight pushing down more or less in the middle of the

board, and the water pushing up more or less evenly across the bottom, a

board will flex a bit, with the bottom in tension, and the deck in

compression. As critical loads are reached in this mode, the deck will fail

first, since most materials - fiberglass, Carbon, Kevlar etc etc - are

only about half as strong in compression, as they are in tension.

Generally, the deck reinforcements will buckle, most

often up (peel strength of glass to EPS low), but sometimes down

(compressive strength of EPS low). Generally, the edges of the EPS core will

be compressed beyond their elastic limit, unable to recover.

A typical Softop buckle repair, then, will require

removal of delaminated reinforcements, some filling of the core, as well as

rebuilding the structure and dealing with the EVA foam pad. |

|

One of the milder buckles to come to me,

with only slight displacement upwards of the skin, and some tearing on both

rails. Cut away enough EVA foam, to allow a

generous amount of overlap for the new fiberglass.

Utility knife, single-edged razor, and sharp chisel

will take off the EVA faster and cleaner then the grinder!

Notice the marked deck depressions from knee

paddling! Notice also the tear on the starboard rail, which appears to have

precipitated this buckle. Some previous impact with a sharp-edged object? |

|

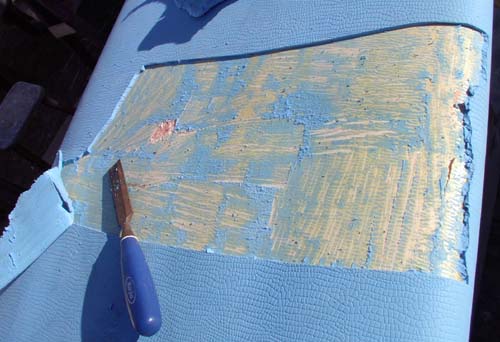

Follow the crack with the grinder to its

very end - no point whatever to slap new fiberglass over broken stuff. If

the repair is to be fair, the new material must REPLACE the broken, NOT be

added over it! |

|

The fiberglass is bevelled on both sides

of the buckle, and all loose material removed, including the little glass

stringers intended to stiffen the deck. Glass

weight is approx 20oz for this 11fter, so I will put (5) layers of 4oz cloth

back. |

|

But first, the substrate needs to be

filled - this a toothpaste-consistency batch of slow Epoxy w/ Q-Cells and

Cabosil, well worked into the voids, to glue down the edges of the old

laminations. Wallpaper knives make good putty

knives! |

|

Five layers of 4oz cloth in 105/205 West

System Epoxy, with the innermost layer just spanning the delam'd area plus

3/4inch, the next another 3/4" wider, etc etc. Everything well squeegeed,

until it becomes perfectly clear and thereby signals an absence of voids and

air bubbles. To duplicate the factory laminate

schedule, I added (4) strips of glass on each rail, staggered by 3/4" each.

|

|

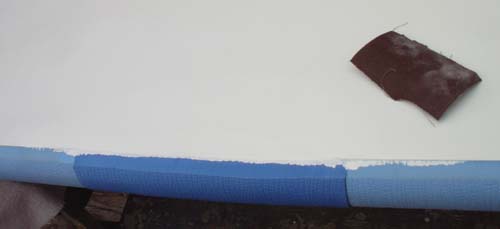

Glass ground, faired with VC Watertight

Epoxy fairing compound, sanded, and coated with Z-Spar high-build Epoxy

primer. In preparation for the new bit of EVA

foam, the edges of the cut-out need to be trimmed true and parallel.

I cut the new piece of EVA at least 2" longer than it

measures, and 1/8" wider for a 12" wide strip such as this. The extra width

forces the edges together and seems to make them stay tight longer. |

|

Once installed with contact cement, I

put a fresh blade into the utility knife and trim the edges of the new strip

of EVA to within 1/8" or so of its final shape. |

|

Then, with the disk sander and 80grit

paper, I finish-trim the edge of the EVA. The secret to success here is to

place the sander so that the disk rotates TOWARDS the board, and not away

from it - which would tear the EVA off, guaranteed! |

|

Edges of freshly trimmed EVA all taped

off, sanded, and coated with LP. Allowed to cure overnight.

To match the matte appearance of the rest of the bottom,

I sand it with 400grit wet & dry paper, then finish by rubbing with a Scotch

"Purple Pad" |

|

Off comes the tape - and, sure enough,

with the surface of the EVA quite porous, some paint ran beneath the

tape.... Sand gently with sharp 80grit

sandpaper to clean up. |

|

Edges all done. |

|

Hit edges all around with a mallet, to set the

contact cement. Clean up pencil marks and stray

blobs of contact cement with a soft eraser.

Hi, Tom :) |

|

return

to Repair Menu |

|