|

|

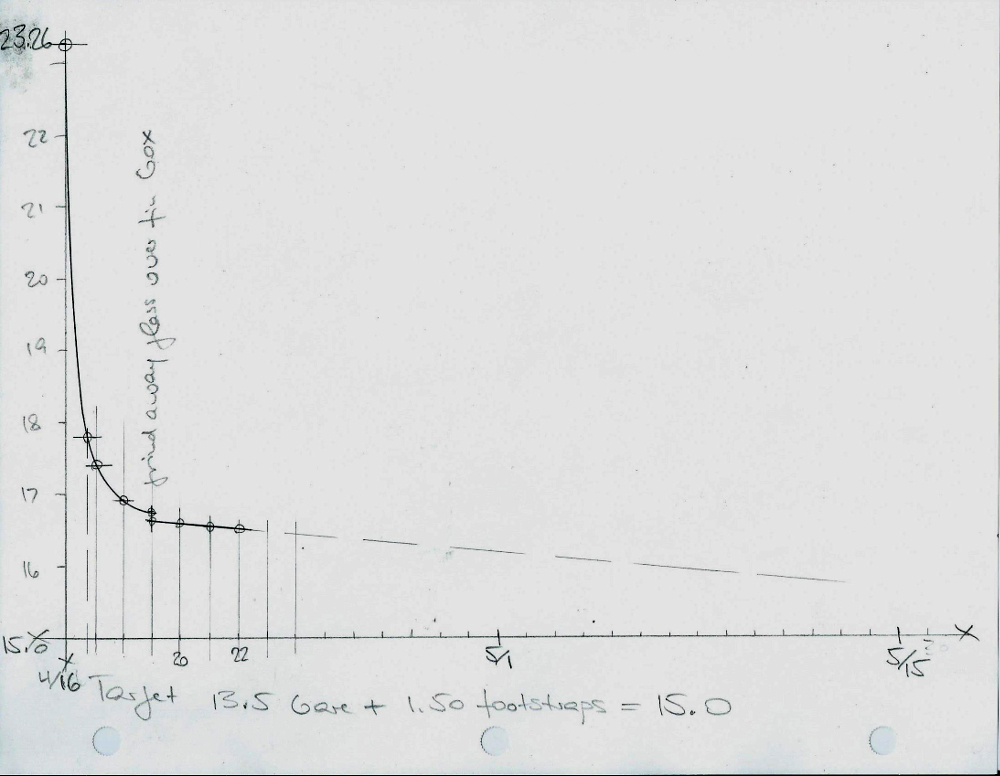

starting weight a whopping 23.26#, with

water sloshing about in the middle |

|

|

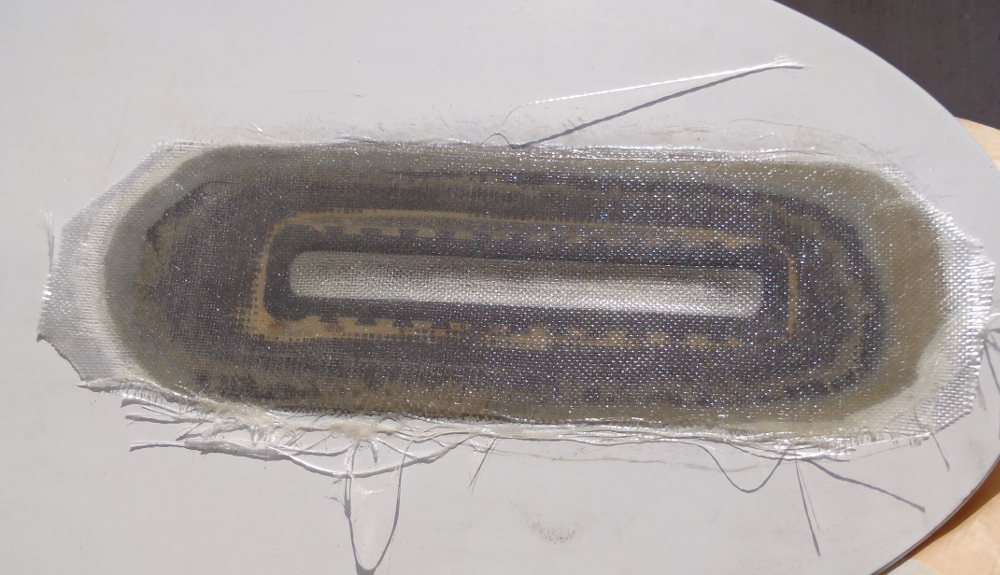

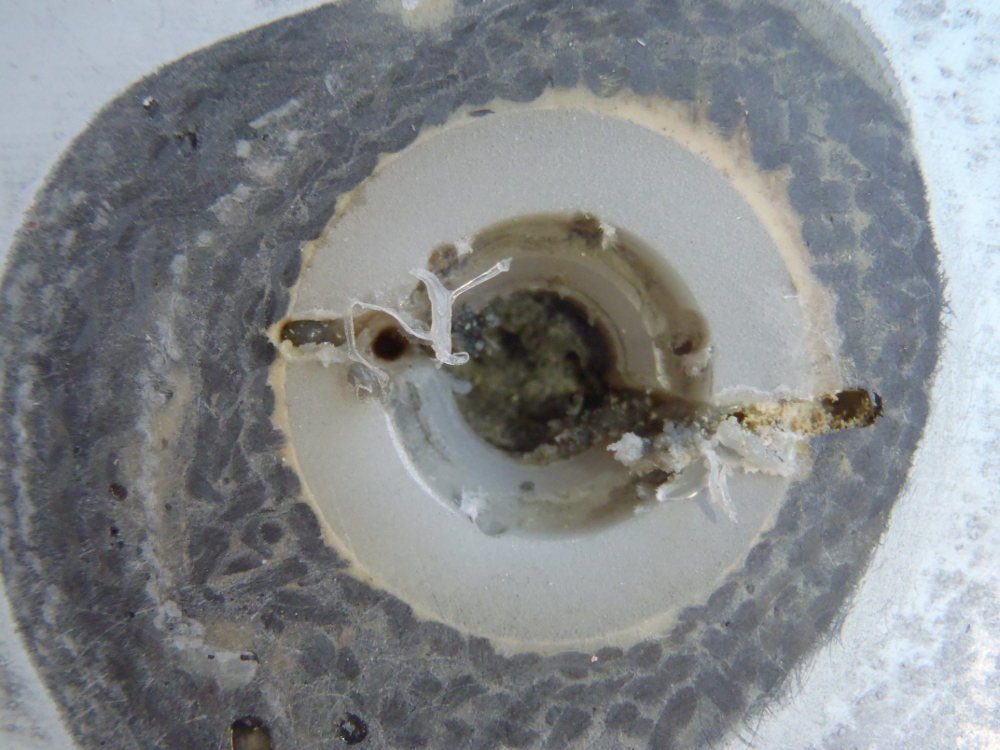

when pressurized, air bubbles from the interface between

fin box and bottom skin; Goretex vent is found punctured and leaking |

|

|

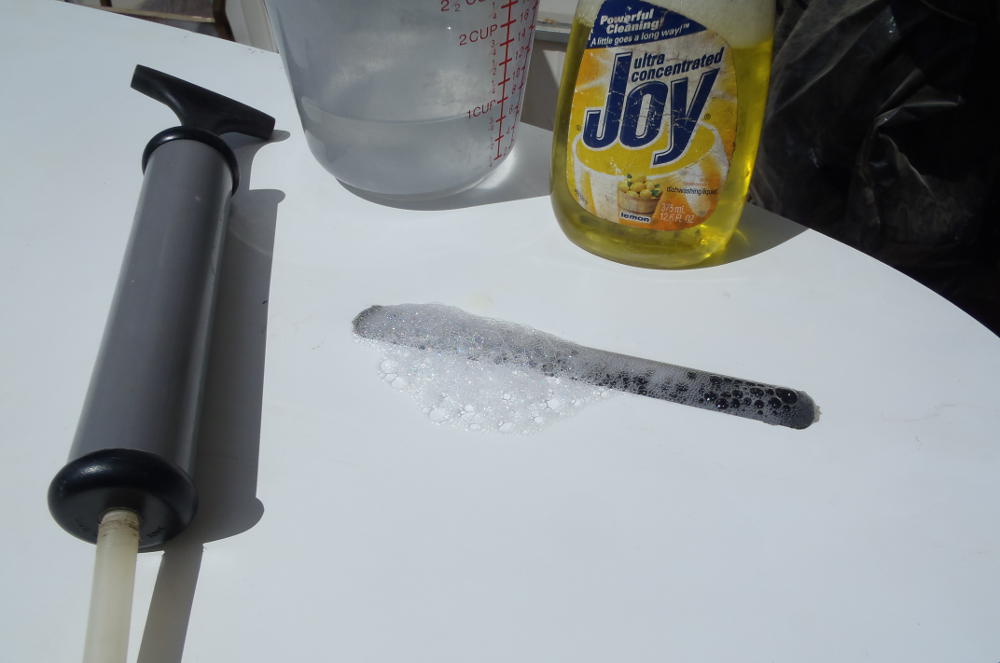

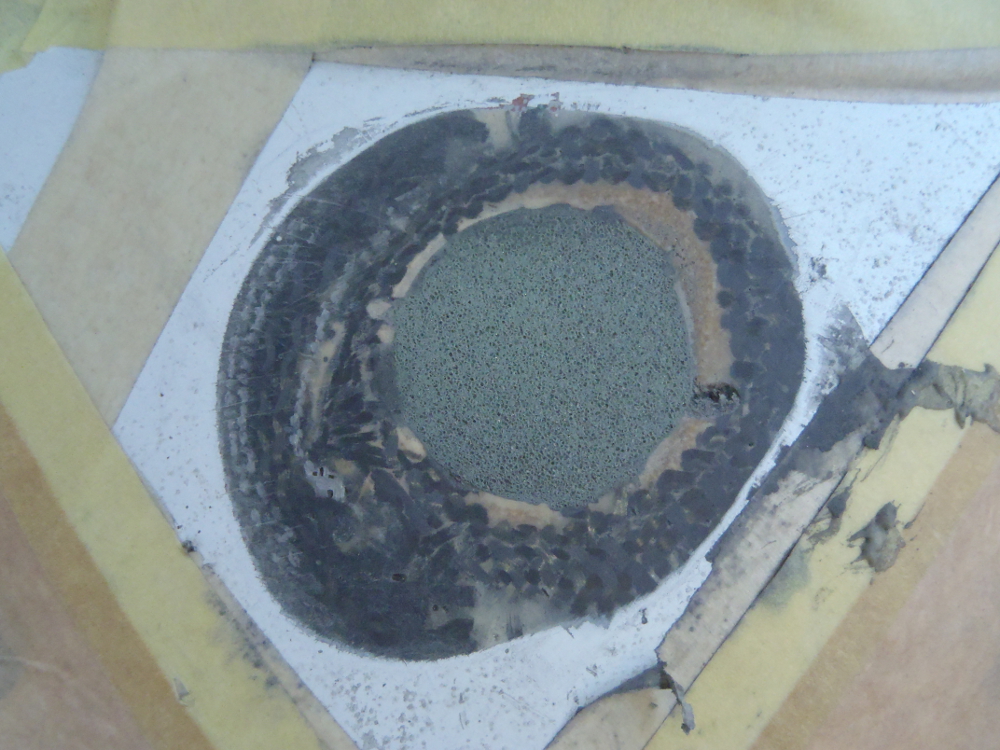

with fin screw holes taped off, the fin

box is filled with soapy water and the board again pressurized. Bubbles

emerge only from the fin box/bottom skin interface, not from the suspicious

router marks on the inside of the fin box |

|

|

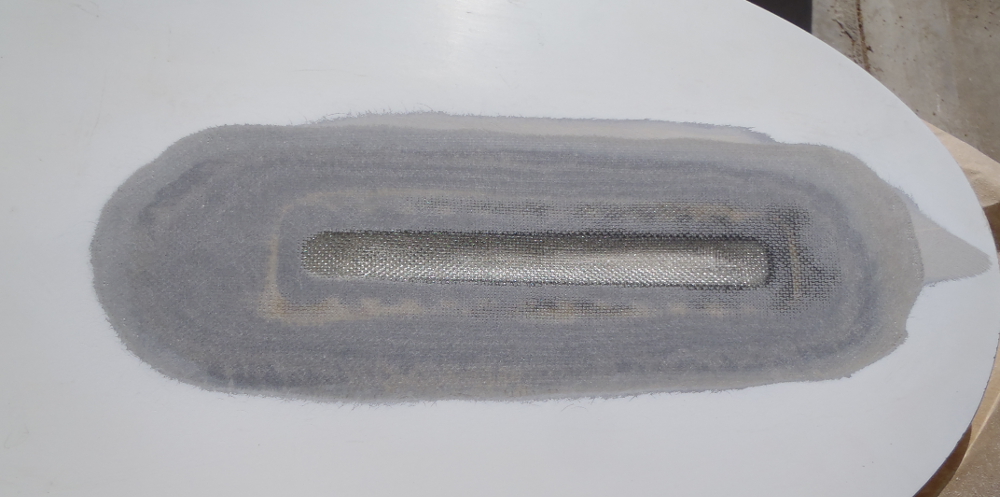

bottom skin ground off, ready for evacuation |

|

|

after extracting almost 7# of water,

the new bottom skin is laminated |

|

|

and ground flush |

|

|

filler, then primer applied, ready for LP topcoat |

|

|

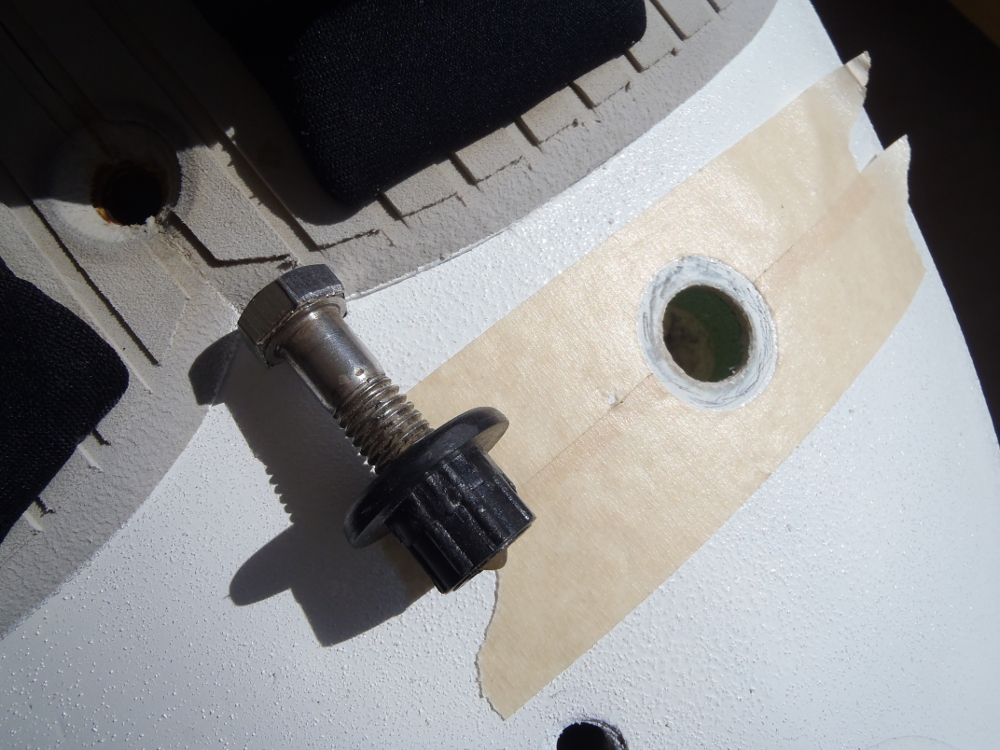

Goretex vent fixture cut in preparation for extraction |

|

|

it comes out relatively clean |

|

|

the substantial cavity is foamed out with 2-part

Urethane, with a 1/2" Divinycell "lid" to support a "proper" vent fixture |

|

|

bevel-ground and ready for outer skin |

|

|

glassed over, then ground flush |

|

|

faired, primed, LP topcoat and non-skid DeckDust applied |

|

|

new Chinook manual vent ready to go in |

|

|

all done! |

|

Return to assorted repairs |